Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

+86-13921192921

Model No.: MRH1200

Brand: Yuda

Place Of Origin: China

Status: New

Warranty Period: 1 Year

Core Selling Point: Accurate Temperature Control, Patented Product, Flexible Manufacturing, Low Maintenance Cost, Sustainable, Low Noise Level, Easy To Operate, Long Service Life, High Rigidity, High-Accuracy, Multifunctional

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction Works, Energy &Amp; Mining, Other

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Marketing Type: Hot Product 2019

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Usage: Sewage,Water Treatment, Gas

Material: Hdpe , Pp, Pe Pipe

Control: Manual

Solution: Butt Welding

Principle: Heat Fusion

Application: Reducing Tee Fabrication

Auxiliary Tools: Radius Saw

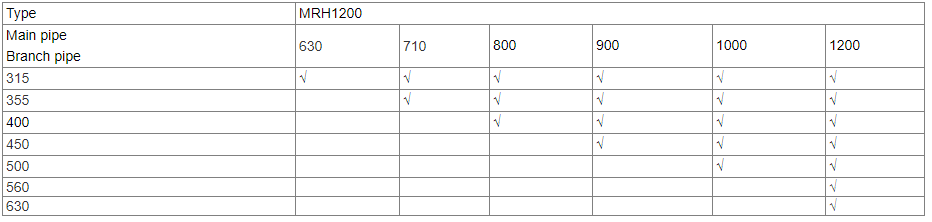

Main Pipe Size: 630-1200mm

Branch Pipe Size: 315-630mm

Voltage: 380v, 50hz

Packaging: Plywood Cases

Productivity: 10sets/Month

Transportation: Land,Air,Ocean

Place of Origin: Wuxi,China

Supply Ability: 10sets/Month

Certificate: CE,ISO9001, SGS

HS Code: 851580

Port: Shanghai,Qingdao,Ningbo

Payment Type: L/C,T/T,D/P,Paypal,D/A

Incoterm: FCA,EXW,CIF,CFR,FOB,CIP,CPT

Product Description

1.Suitable for fabricating PE reducing tee in a workshop. Integrated function of welding and taping enables it can complete the whole fabricating process

2.Removable PTFE coated heating mould

3.Control panel accompaines with CNC system to eliminate any risk of error due to the operator

4. Full-Automatic welding procedures with PLC and Touch screen

5. Welding statistics recording and printing function.

6. Linear guide ways are equipped with main pipe clamps, branch pipe clamps, knife tool and heat mould

Optional Parts:

* Heat Moulds

* Drilling Tool

Detailed Photos of Polyethylene Saddle Fusion Equipment

Product Parameters

| Model | MRH630 | MRH1200 | MRH1800 | MRH2000 | |

| Working range | Reducing tee | ||||

| Max. Temp heating plate | 270ºC | 270ºC | 270ºC | 270ºC | |

| System pressure ranges | 0~20MPa | 0~20MPa | 0~20MPa | 0~20MPa | |

| Working voltage | 380V,50Hz | 380V,50Hz | 380V,50Hz | 380V,50Hz | |

| Heating plate power | 6 KW | 16 KW | 25KW | 32 KW | |

| Hydraulic unit power | 2.2 KW | 2.2 KW | 3KW | 5.5KW | |

| Drill motor power | 2.2 KW | 3 KW | 4KW | 5.5KW | |

| Power | 10.4KW | 21.2KW | 32KW | 46KW | |

Production Process

Polyethylene Poly saddle fusion Machine Exported

FAQ

A: It is available, you can choose to come to our factory to learn machine installation, operating, machine maintenance etc, also we can arrange our engineer to your factory for detailed training,even online training available too.

Contact Information

Product Categories : Workshop Fitting Machine > Saddle Fusion

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.